Air quality in extraction facilities is an oft overlooked topic. Focus – rightfully so – tends to be on explosive and flammable hazards. But health risks to personnel from long-term exposures can pose an equal if not greater risk to the entire industry. Health risks are unavoidable if proper precautions are not in place. Extraction facility operators need to be fully aware of these risks in order to prevent them.

Unregulated Risks in Extraction Facilities

Cannabis and hemp extraction facilities are largely unregulated. As such, these facilities can pose significant health risk to personnel. These risks are primarily from continued, long term exposure to chemicals.

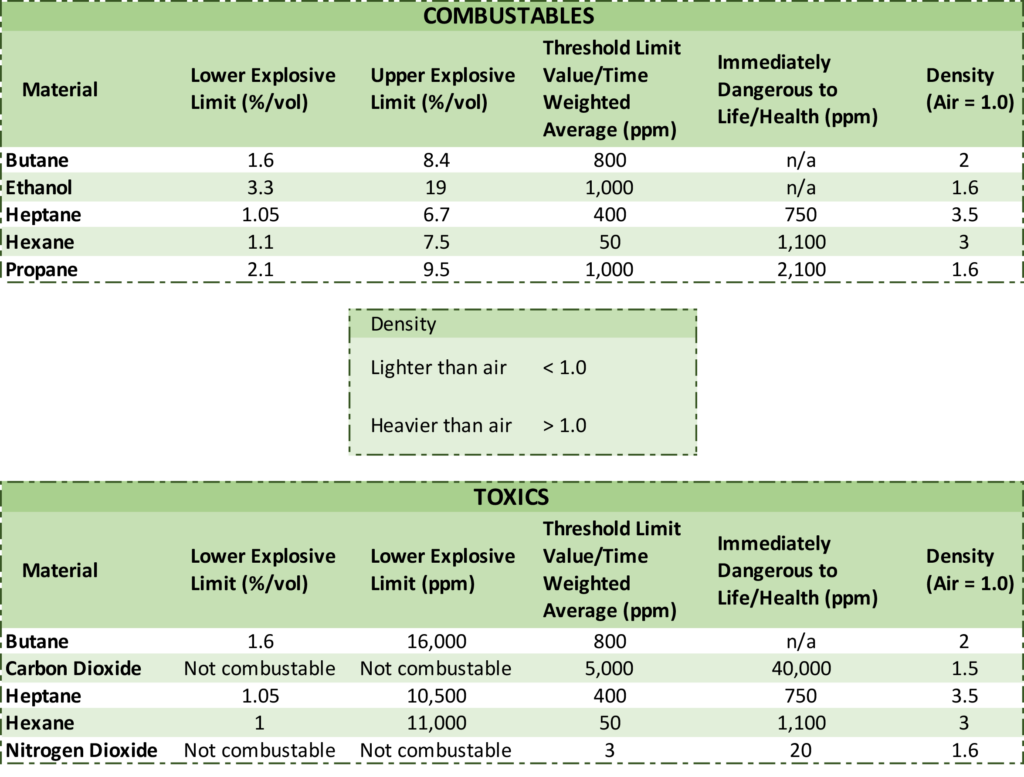

- Numerous chemicals are used in both the initial and final processing of cannabis and hemp products. Ethanol, butane, propane, hexane and heptane are just a few to be named. There are also secondary fluids – such as carbon dioxide or liquid nitrogen – used in support of some processes. All of these chemicals can exist in a gaseous phase and can permeate a facility undetected. While some of these chemicals – such as butane, propane and ethanol – are monitored for flammability, they are not monitored for personnel health exposures.

- In a normal working environment, humans are likely to be exposed to immediate high concentrations of chemicals at the source. (i.e. cracking open the honeypot or cleaning the isolate reactor.) The hydrocarbon or ethanol sniffers several feet away are unlikely to detect these higher concentrations because the chemical gas is quickly diluted when dispersed.

- Carbon dioxide and nitrogen are considered asphyxiants. However, long term exposure to low level concentration is not usually a concern.

- The use of post processing chemicals in the formation of isolates in sealed reactors are of great concern. Health limits are inverse to flammable limits. For example, heptane and hexane are health hazards before they become flammable hazards. Heptane health exposure (IDLH – Immediately Dangerous to Life or Health) limit is 750 PPM. Yet its lower explosive limit is 10,500 PPM.

The key takeaway is to not overlook risks associated with long term chemical exposure. It is also to be aware of the fact that fume or gas detectors installed within facilities or extraction rooms are designed with detection and alarm limits for explosion prevention. These limits are far greater than allowable health limits. There are plenty of industry stories about leaky systems, mishaps and other situations that get privately or publicly shared. [i][ii][iii] All these stories were preventable.

How to Provide Safer Environments in Extraction Facilities

To be clear, we are not indicating that the management of these extraction facilities are purposefully ignoring safety hazards. We know that everyone has the best intentions to operate the cleanest and safest facility for personnel and products. Rather, we point out that there has been history of a concerning knowledge gap. What we try to assist with at Element Grow is closing that gap. We do this by researching the risks and designing product and system solutions to provide safer environments.

Other ways you can establish extraction facilities that are safer for personnel:

- Provide proper OSHA approved training for all personnel working with hazardous materials. Certifying each of your employees who will be in the presence of these materials should always be the first step.

- Ensure that the process, in normal working conditions, is leak free. Visual inspection, bubble tests at fittings, or gas/chemical sniffers are a must before operating any piece of equipment. Document all readings, both good and bad. Provide corrective action around the bad readings. Make sure to keep good records in case of audits by OSHA or local authorities.

- Always provide appropriate personal protective equipment (PPE), whether gloves, goggles and/or chemical masks. Additional layers of protection can come in the form of air filtration and monitoring equipment. This ensures personnel are working in safe respiratory environments.

- In all facilities, the cheapest and most efficient way to provide safe working environments is to provide fresh air. Dilution and appropriate exhaust points outside the building to vent gases or fumes generated in the extraction process can help do this. Element Grow air filtration products are a guaranteed way to provide fresh, filtered outdoor air and are able to meet a variety of filtration needs and capabilities.

- The foundation of any GMP plan and facility should be clean filtered air. The Element Grow suite of products are specifically designed to support GMP operations. They do this by providing quality air filtration that is paired with monitoring capabilities. Care and caution should be taken to not recirculate hydrocarbon or other gases or fumes. This can be done with activated carbon filters that ensure the chemical will not exothermically chemically react (i.e. cause a fire) within the carbon bed.[iv]

Extraction facilities and operators need to be diligent in evaluating and addressing all possible risks to the health of the personnel and the facility. Element Grow can help you do this with products that are designed around internationally agreed upon building codes and standards. This ensures all products meet current and best practices for a safe operating environment.

[i] https://www.osha.gov/dts/hib/hib_data/hib19970730.html

[ii] https://www.abc.net.au/news/2010-10-26/workers-poisoned-while-making-iphones/2311522

[iii] https://www.nytimes.com/2011/02/23/technology/23apple.html?pagewanted=all