Products

Puren UVC Fixture

Mercury vapor lamp is designed to fit into commercial available strut channel framing for a variety of industrial, processing, and greenhouse applications.

Katana Handheld UVC Light

Portable and highly adaptable LED UVC lights specifically designed to access those hard to reach places and for direct exposure to contamination.

Katana Mounted UVC Light

Sleek design and flexible mounting allow you to provide powerful UVC sanitization to meet the demands of any application.

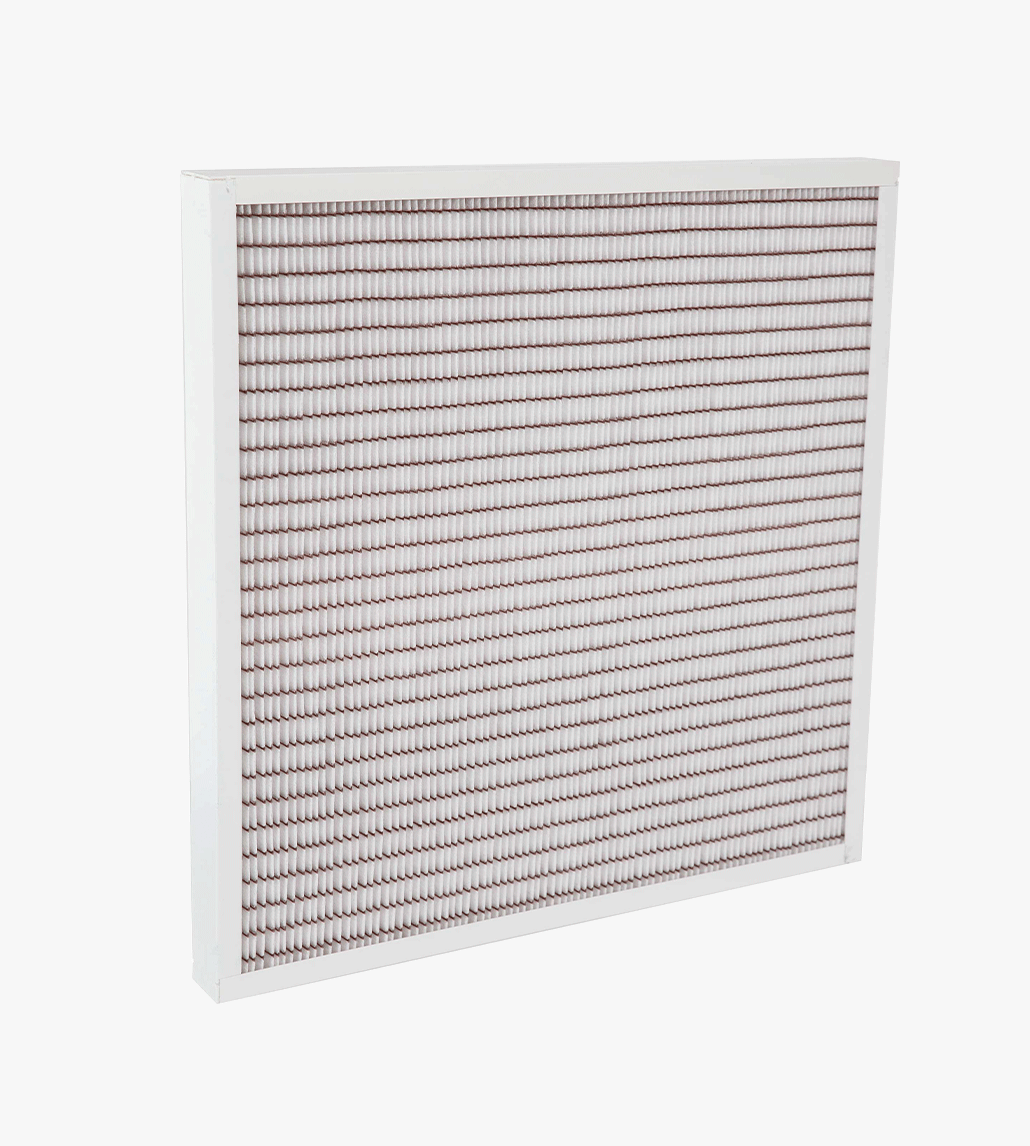

E-Series Air Filtration

Powerful fan filter units and monitoring system for contaminant sensitive environments where protection of people or products is critical.