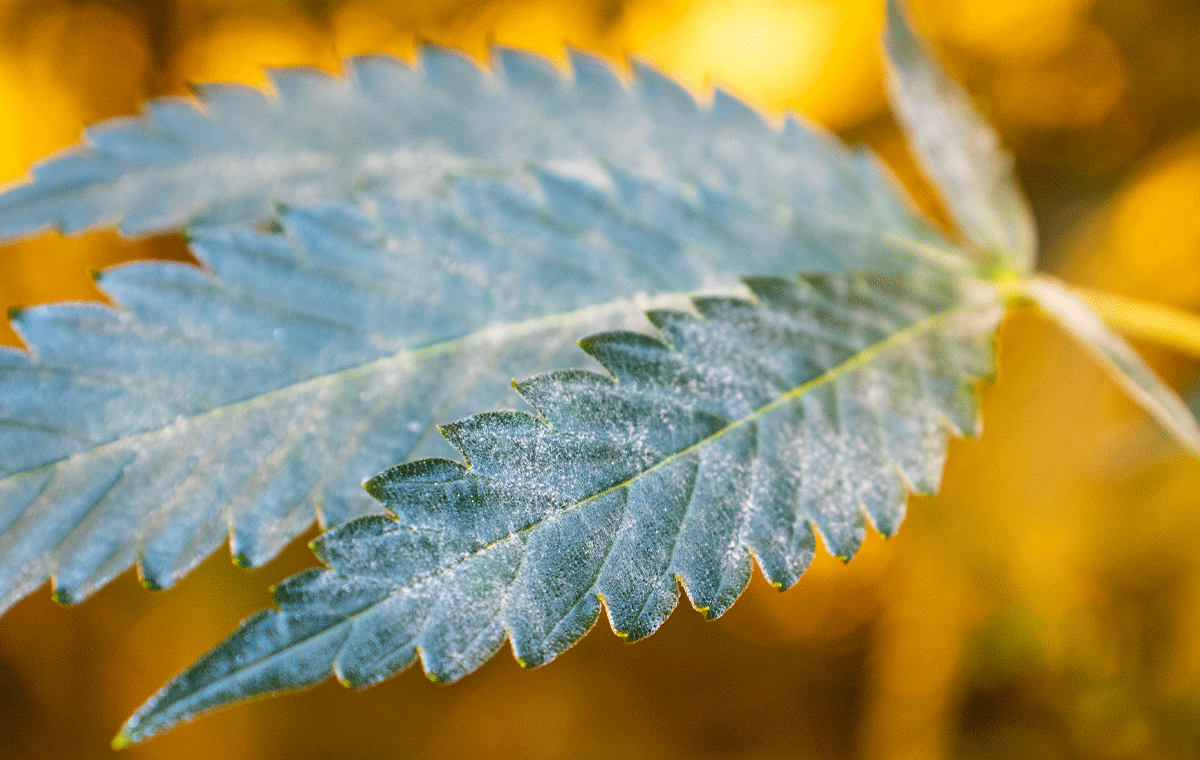

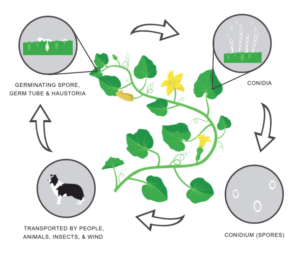

You work hard to provide quality indoor crops. Not only as your livelihood, but to support the livelihood of others. Threats to indoor crop quality come unappreciated and at times, financially devastating. One of the most widespread threats is powdery mildew. Almost no plant is immune. Appearing first in isolated spots as very small, grayish-white circular dustings, powdery mildew rapidly becomes denser. If you do not act quickly, leaves of plants will brown and die.

By the time you can see powdery mildew with the naked eye, it has already established itself on plants. Usually much more than you can see at that moment (which is why a powdery mildew situation often feels like it “blows up” rather quickly). But this does not mean all is lost! There are a range of steps to be taken to control and eliminate powdery mildew.

Step One

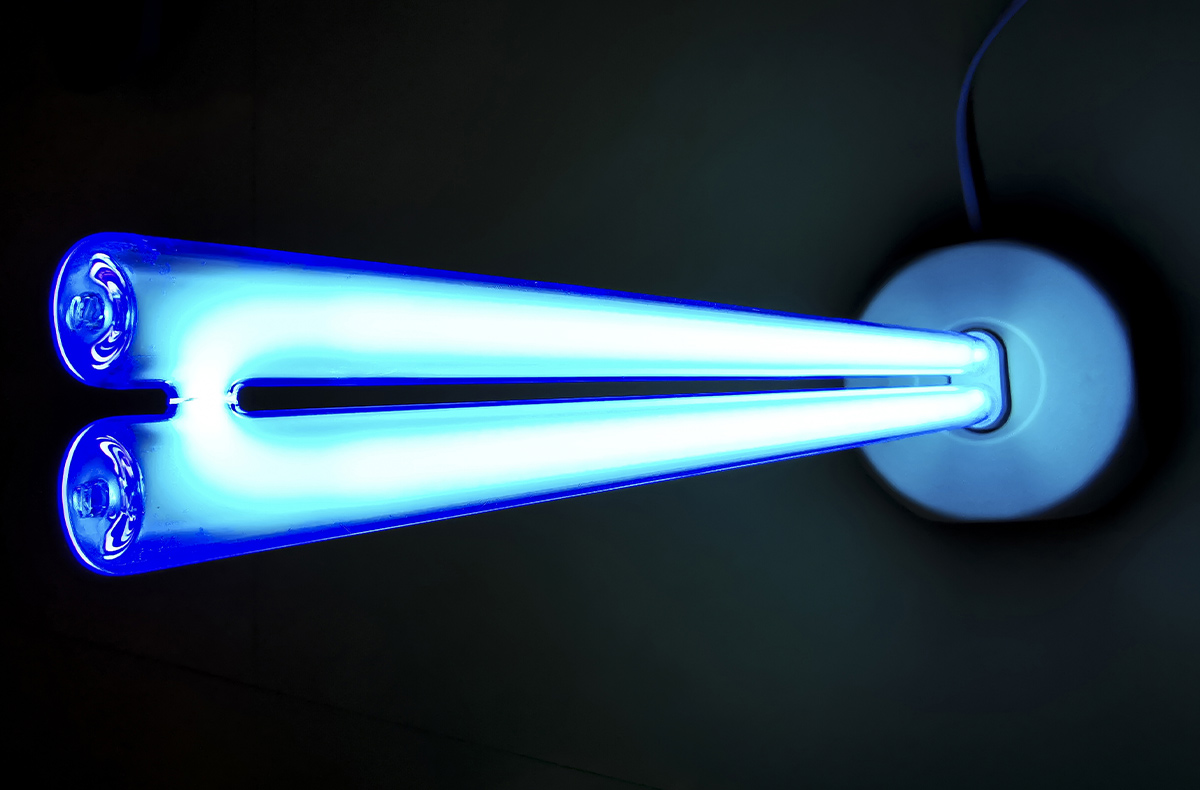

Powdery mildew spreads quickly due to its production of airborne spores. The first step in mitigating this spread, is to ramp up (or institute) air filtration. It is of course important to filter air coming in from outside and most facilities should have this already in place. But contaminants such as powdery mildew can also be brought in on other plants, people, equipment or animals. General HVAC systems will not provide the power needed to stop the spread of powdery mildew (nor is such a system easy to clean and sanitize after an outbreak). That is why utilizing an industrial strength air filtration system in your rooms is vital to not only mitigation of powdery mildew, but for prevention as well.

Step Two

Step Two

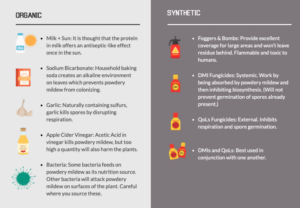

There are two different remediation approaches you can take to combat powdery mildew – organic or non-organic. Common household substances can be used to maintain organic status of your products, such as milk, baking soda, apple cider vinegar and hydrogen peroxide to name a few. It should be noted that even when using these typically harmless substances, special attention should be paid to make sure products being used are approved organic by state and federal agencies. There are also more potent solutions that can be classified as organic, such as burning sulfur. (Again check with your state’s department of agriculture and testing limits.) There is also innate hazard with burning sulfur to consider… it is toxic to humans and very bad for electronics and hvac equipment if they are not designed to withstand this level of corrosive substances.

If maintaining an organic status is not a concern, a variety of chemical applications are available. These can include foggers or bombs and fungicides. The most popular fungicides for powdery mildew are demethylation inhibitors (DMIs) and quinone outside inhibitors (QoIs).

Step Three

Step Three

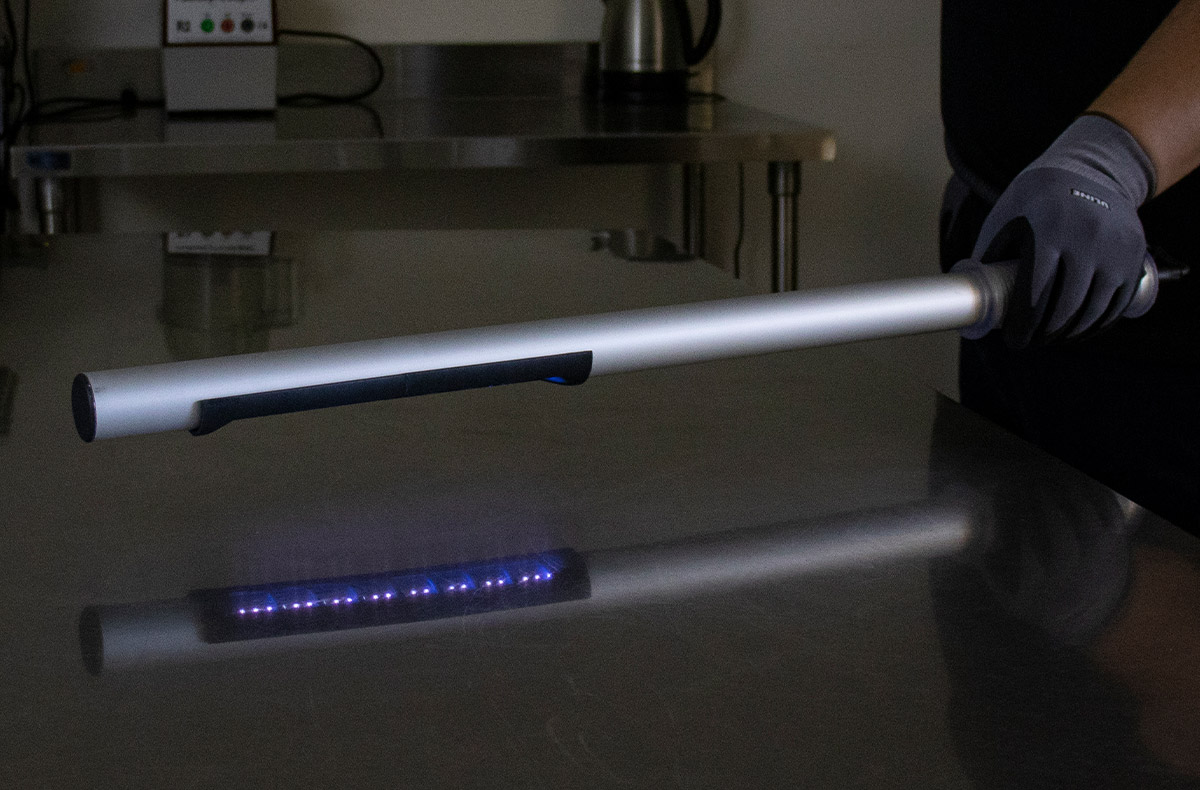

Powdery mildew spores can exist in a dormant state for some time. Even if you feel like you have the outbreak under control or eliminated, until you thoroughly clean your indoor grow space you cannot ensure you will not experience another outbreak with your next crop. This includes all equipment in the room, which add a level of complexity. The ability to clean and sanitize your indoor growing and processing spaces as well as the equipment used in them is also vital for meeting GMP standards.

Step Four

In order to better prevent recurrences of powdery mildew, a strong integrated pest management (IPM) plan should be maintained. This layered, ecosystem-based approach is all about taking habitual actions before there is an issue. These controls and preventative measures are especially important when it comes to Good Manufacturing Practice guidelines. While monitoring is a foundational piece of any IPM plan, it is also labor intensive and time consuming. Utilizing GMP approved tools that not only help monitor but also provide data for reporting and alleviate this common obstacle. Passible sampling with test plates and colony counts is also an option, albeit more time and labor intensive than more automated approaches, Likewise, a solid foundation of cleanliness, especially in regard to clean air (mentioned in step one) and the ability to regularly sanitize environments and equipment, will help you operate your IPM plan more efficiently.