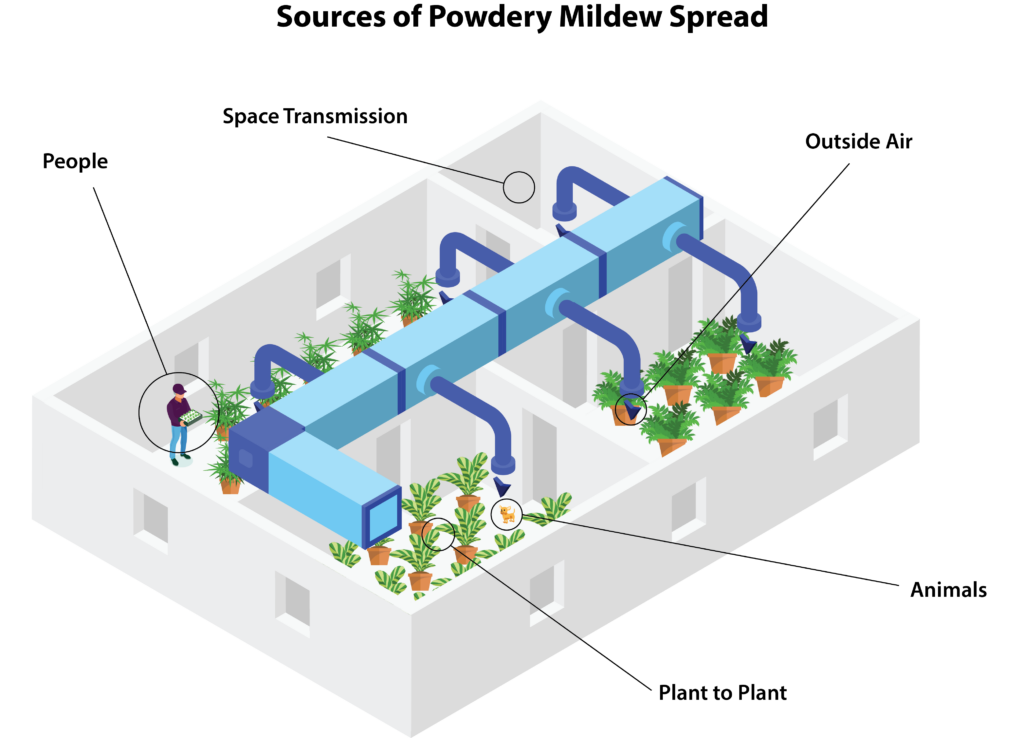

Powdery mildew. A common and dreaded fungal disease affecting a wide range of plants, especially in indoor environments. Transmission of powdery mildew spores is primarily airborne, accentuated by increased airflow. But what are the sources of powdery mildew? How does it invade indoor spaces?

All it takes is one spore.

Outside Air

Plants need fresh air. As such, every indoor growing environment requires some sort of air exchange. Ventilation and airflow get a lot of attention. But if adequate filtration is not in place, air coming from the outside can carry a range of contaminants, including powdery mildew. The standard design protocols used by most HVAC professionals are not suited for the unique needs of indoor growing environments.

Organic Matter Transmission

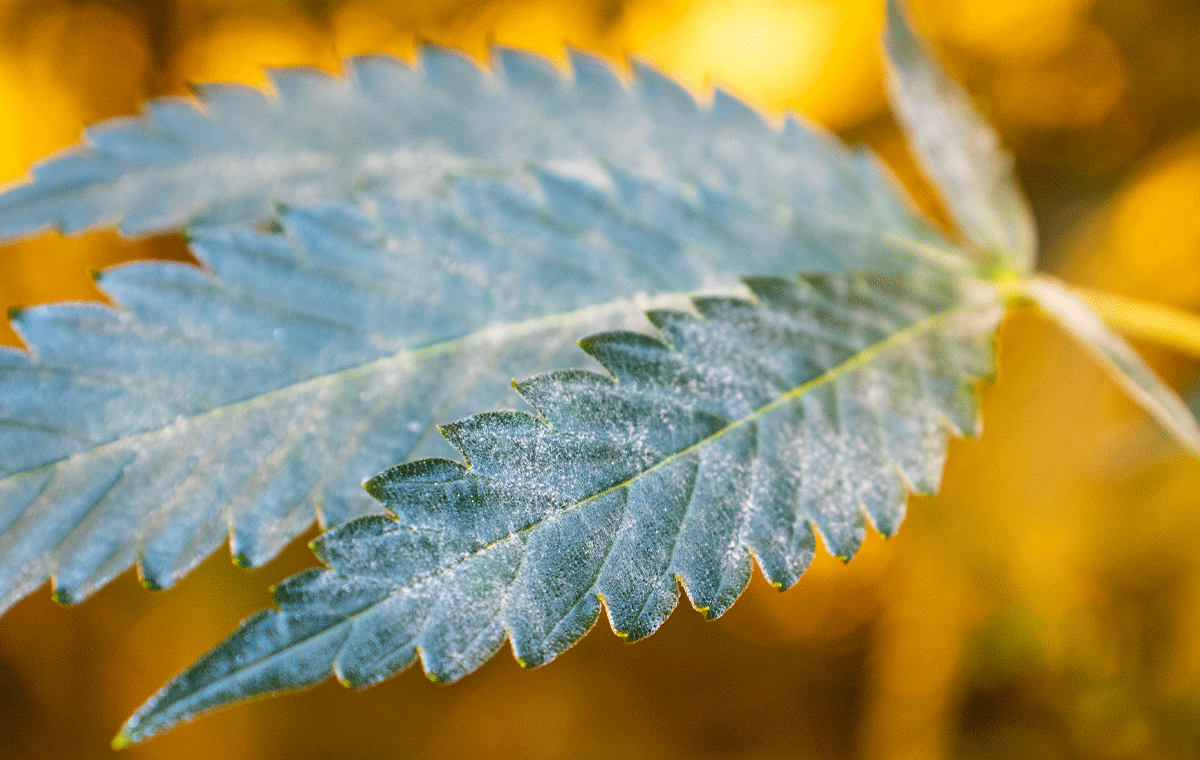

Powdery mildew and other contaminants are easily transmitted when introducing new plants to your grow (such as clones) and moving plants between your indoor spaces. Growing media is another potentially contaminant source, especially if locally sourced. (We are very supportive of sourcing locally, but are realistic about the possibility of accidental exposures and transmission that can occur via any growing media. Especially if the media is not triple-washed and pH-buffered like many manufactured medias.) Powdery mildew is nearly undetectable with the naked eye and spores can live in soils and organic matter. This makes it easy to transport contamination into spaces shared with healthy plants. Depending on conditions, powdery mildew spores will overwinter in soil and organic matter. Some research shows spores surviving up to three years.

Tips to help prevent transmission:

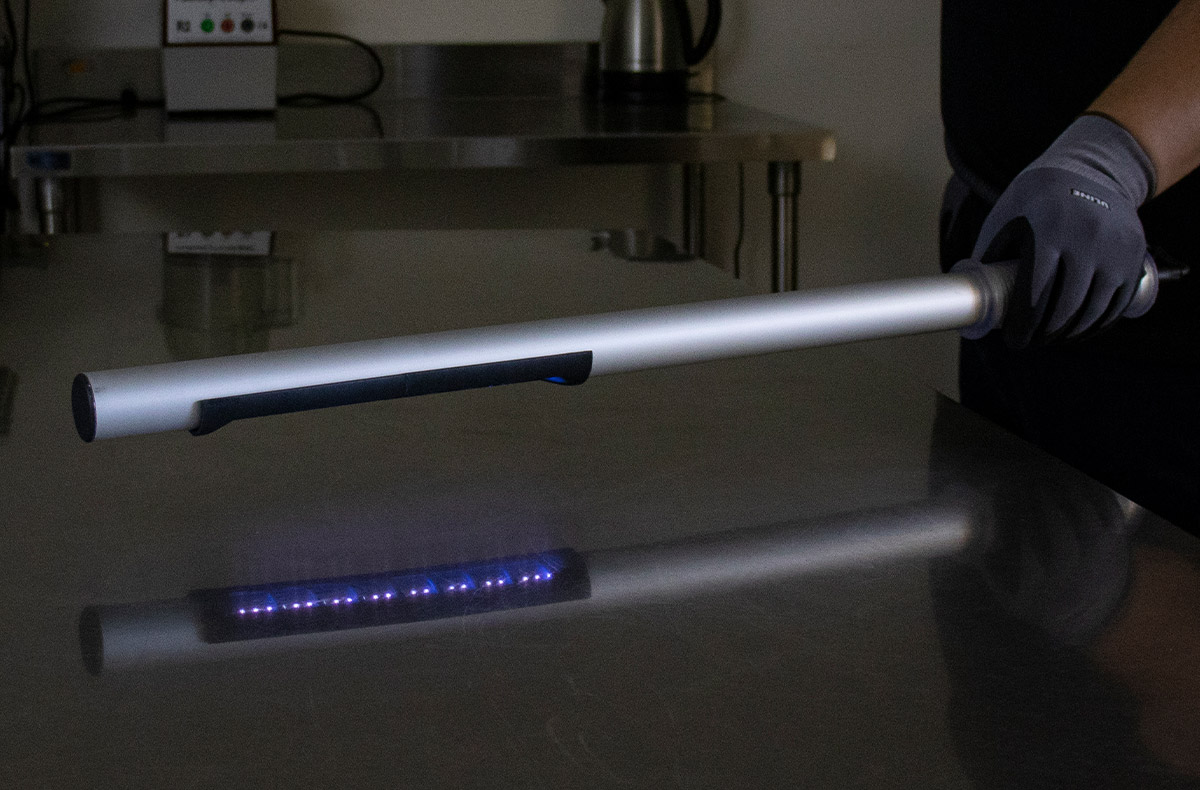

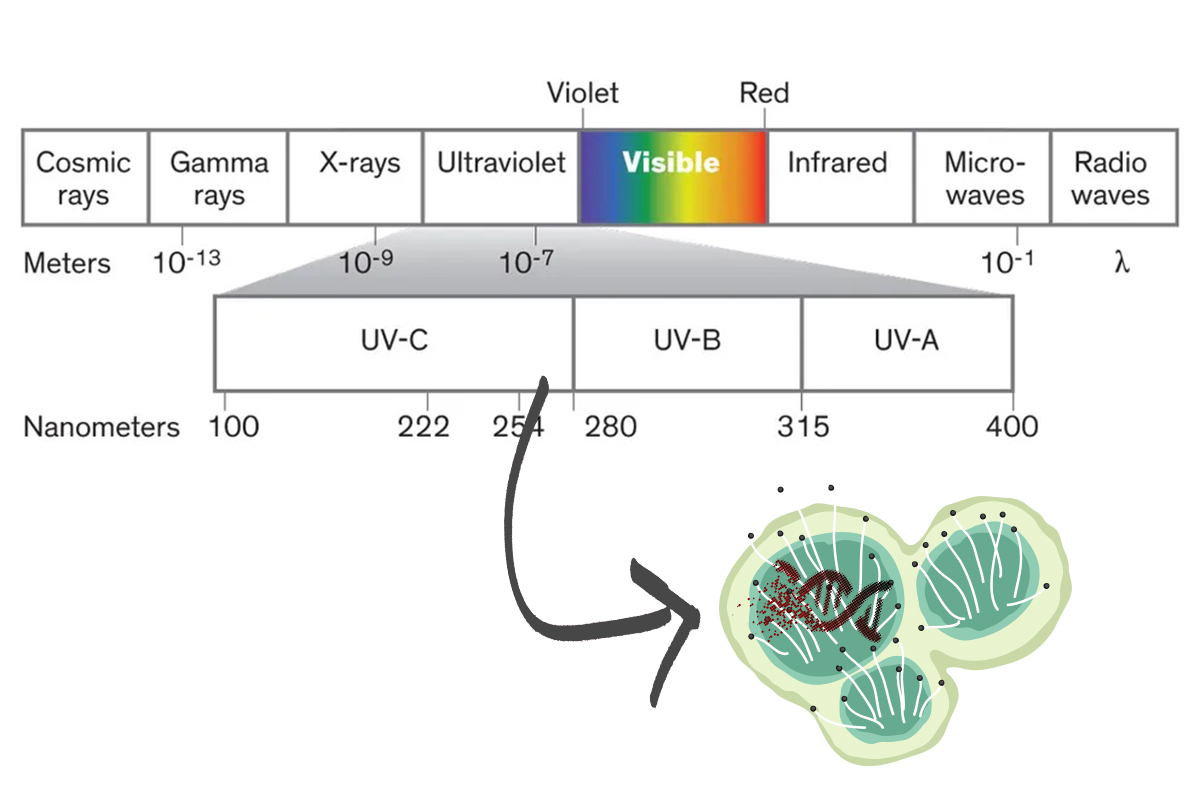

- When transferring new plants/clones, make sure any pots – whether new or being reused – have been thoroughly cleaned and sanitized. If you avoid chemical sanitation, use UVC light to sterilize them after washing and drying as an effective alternative.

- Thoroughly inspect all new plants for pests or fungus. Signs such as white, yellow brown or red spots, white fuzzy patches, small specks, blistered or glossy leaves can be signs of contamination.

- All plants should be quarantined for 7-10 days. Utilize specialized, industrial filtration units in quarantine rooms. Make sure the units can be fully sanitized in between uses. This will rapidly capture powdery mildew and other contaminants, preventing spread from that location.

- Know where your grow media is coming from as well as the processes used to cultivate and store it.

- Avoid overcrowding your plants. The overlapping and rubbing of leaves can affect the plants ability to transpire efficiently and create humid spots. This increases the spread of powdery mildew as well as pests and other problems.

- Invest in adequate air flow, ventilation and purification. Fans, HVAC and portable filtration units work together to maximize pest reduction and plant health potential.

- HVAC systems will introduce organisms if not properly designed. And they are inherently places where organisms concentrate and multiply. Retrofit your HVAC system with units specifically designs to capture these organisms. Units easy to sanitized inside and out prevent the growth and spread of microorganisms.

Space Transmission

Standard procedure is to properly clean and sanitize each space and all equipment in between crops. Not doing so often results in healthy plants becoming contaminated once placed in that space.

Tips to help prevent transmission:

- Clean supplies thoroughly, whether brand new or used . This includes everything – pots, tubes, tools, ect. If you avoid the use of chemicals, UVC light is an extremely effective sterilization alternative.

- Have a dedicated set of tools for each grow space. This helps avoid transfer of contaminants from room to room. If this is not possible, implement a thorough sanitation process for all tools after each use and before use in a new space. If a tool cannot be chemically sanitized, utilize UVC light. Thoroughly wipe the tool down first and making sure the light reaches all surfaces/spaces of the tool.

- Vacuum up any and all debris. Use a vacuum with a true HEPA filter to avoid blasting mold spores or pest eggs back into the room. Use a vacuum bag when possible. Dump shop vacs or remove vacuum bags outdoors and away from any openings into the building (doors, air intakes, etc.).

- Sanitize all surfaces. For walls and ceilings, use a small pump sprayer. For floors, use a mopping system and food grade hydrogen peroxide or bleach (make sure to wear proper PPE equipment).

- Use even and overlapping strokes when spraying and mopping. This will ensure 100% coverage of the surface.

- Make sure you adequately clean the variable surfaces in corners and around things like vents.

- UVC light can get those hard to reach places or be applied in lieu of chemicals.

- For additional certainty, apply a fresh coat of epoxy (or other moisture sealable paint) that has an anti-mildew additive on the walls and ceiling.

- During and after these cleaning processes, utilize industrial strength, fully sanitizable air filtration units. This provides additional protection against contamination exposure and spread.

People and Animals

Powdery mildew spores can attach to and be carried by people. Indoor growing environments benefit from standard operating procedures that prevent human vector spread of contamination. Not only whenever people enter the building, but also when moving between rooms. And while we all love the shop or office dog, animals – just like people – can act as vectors for contamination in indoor grows.

Tips to help prevent transmission:

- Do not allow animals into grow rooms or surrounding areas, period. If an animal must be present onsite (such as the lovable office dog), do not allow employees working in grow spaces to interact with the animal during work hours.

- Invest in things such as disposable shoe covers and disinfecting mats. Have these inside each facility door as well as grow room doors as well as plastic curtains inside each entrance. Likewise, ensure all floor and wall surfaces in the facility can be wiped down and are not made of porous materials.

- Never dry sweep a floor. This will send spores, bacteria and other airborne micro-contaminants back into the air (something harmful to plants and people).

- Create positive air pressure inside each grow room. This will help prevent contaminants being drawn in from the outside when people are entering and leaving the room.

- Install air showers at every entrance to the facility. Require all employees and visitors to pass through them.

- Install onsite showers. Require any employee entering grow rooms to utilize these showers and change into clean work clothes after doing so.

- Work clothes should be washed and stored at work.

- An ideal situation would provide different sets of clothes for each area or room to prevent cross-contamination, especially if dealing with a contaminated room.

Your Contamination Experts

At Element Grow, we strive to help you meet Good Manufacturing Practices with products and support that provide functional solutions through affordable, easy to use applications. Our products can easily be cleaned and sanitized and provide a solid foundation for GMP in your indoor grow facility. We understand the challenges of designing complex agricultural and bio containment systems. Our products are designed to meet your unique needs while also remaining user friendly, functional and efficient – this is our passion. For more information on how Element Grow can help you meet GMP requirements as well as meet your individual needs, contact us at info@elementgrow.com or by calling 1-888-353-6681.