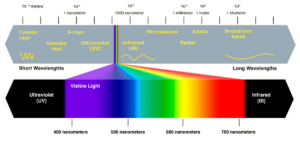

UVC is a prominent topic. But what exactly is UVC and how can it help you eliminate powdery mildew and other contaminants? Natural light is an amazing resource of energy for humans, plants and animals. At a young age we observe and learn about the colors of the rainbow. Every color in the rainbow is a spectrum of energy and wavelengths. Infrared (or red) light is considered low energy. As we move through the color spectrum from red to green to violet, the wavelength decreases and frequency increases. Higher frequency means higher energy. When outside, we wear sunscreen to protect us from UV rays that cause sunburn. Specifically those in the UVA and UVB spectrum. These rays are part of the visible light spectrum. Also part of the visible spectrum are UVC rays. We typically do not worry about UVC rays while outside because they do not penetrate the earth’s atmosphere. Nearly all human risk from UVC is from manmade sources.

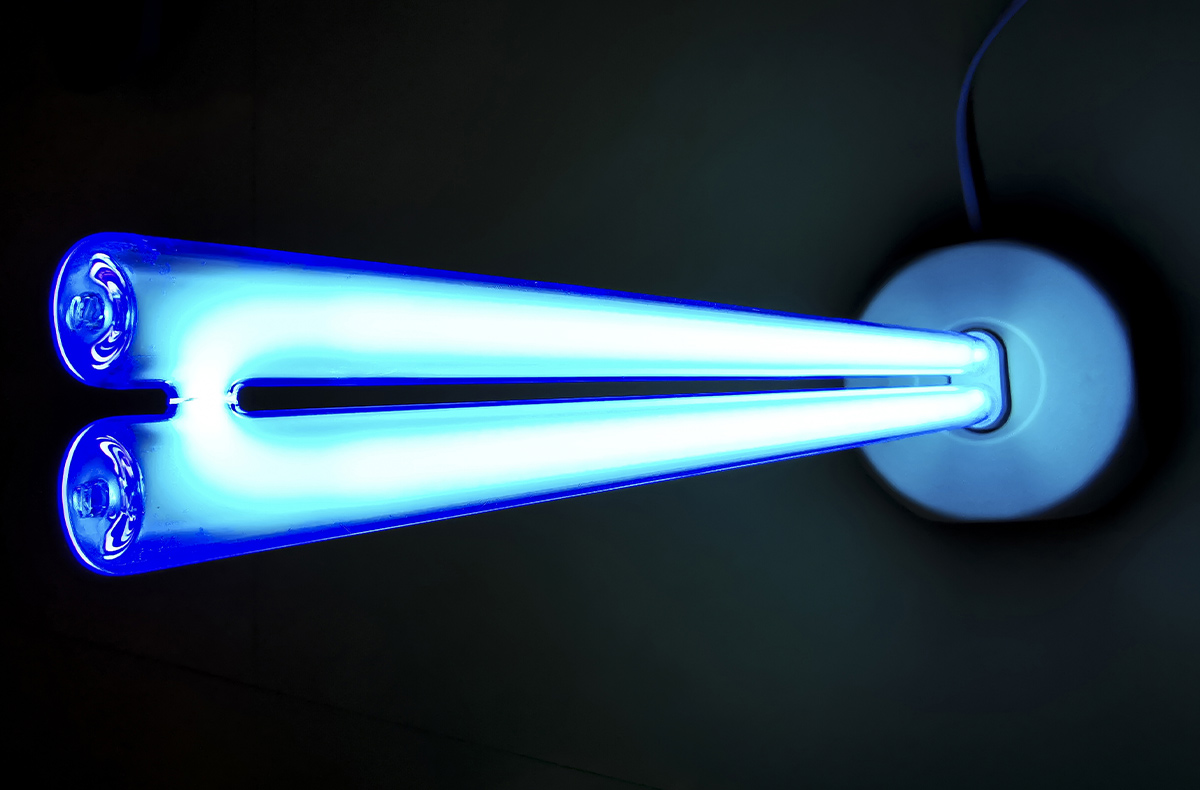

The UVC spectrum is unique because it contains enough energy to physically destroy DNA in less time than the other UV spectrums. However at shorter exposure times it poses less danger to plants and humans, but remains effective at killing viruses, bacteria, molds and mildews. It is an effective chemical-free tool for disinfection and sterilization. Research [i] supports UVC wavelengths at 265 nm as the most efficient at disinfecting biological contaminants.

UVC in Cannabis and Hemp

Molds are silent killers of both plants and profits in cannabis and hemp industries. Molds such as powdery mildew, bud rot or fuzzy white mold frustrate growers and jeopardize crop cycles. UVC light is a powerful alternative to the chemical-based solutions commonly employed (especially for products for human consumption). Powdery mildew spores spread quickly within an enclosed environment. Crops are already compromised by the time it is visible on plants. Immediate action is required to arrest the spread of powdery mildew, otherwise loss of crop can be expected.

UVC Best Practices

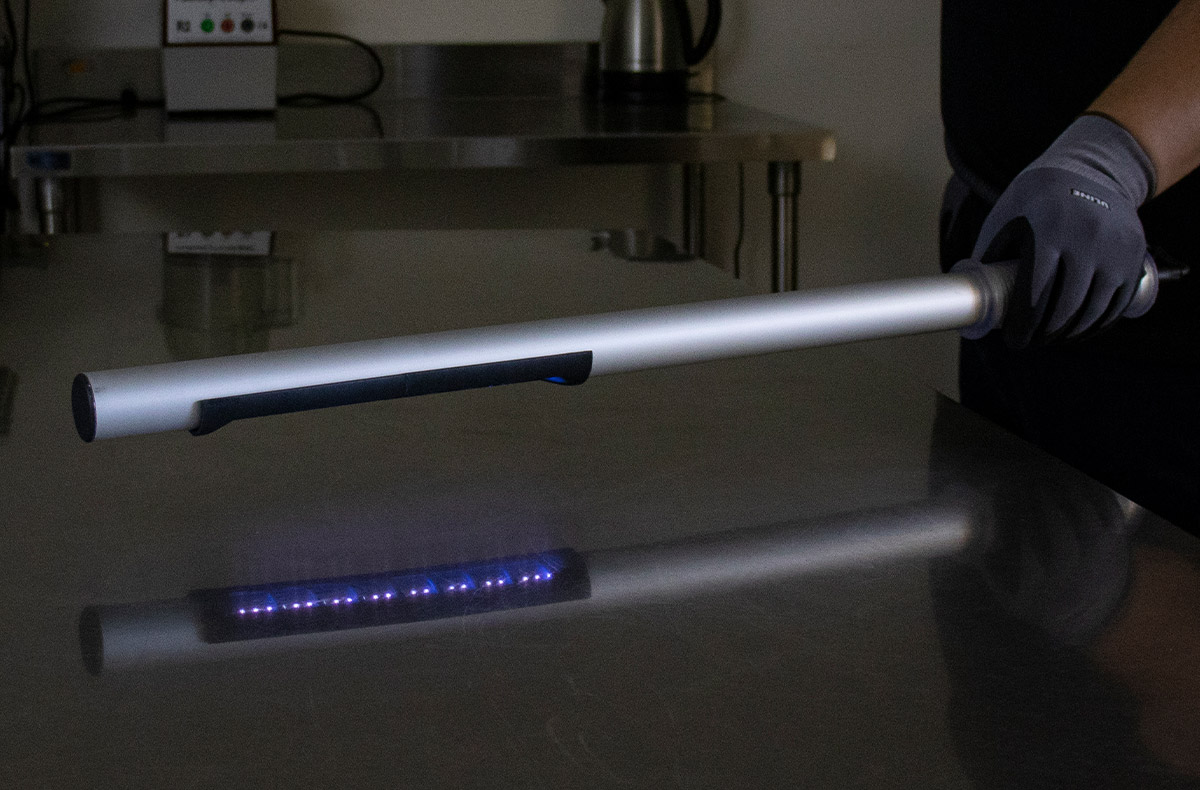

A handheld UVC light source is one of the most efficient, reusable, chemical-free tools you can apply on all plants and surfaces. It is an excellent addition to any integrated pest management plan (IPM) and enhances best practices. When an outbreak occurs, concentrate UVC light on the visible powdery mildew spots. Visibility of powdery mildew means spores are already being emitted and spreading throughout the grow space. Once UVC has been applied to all visible spots, apply it to the surrounding areas. This helps control spore populations and mitigate spread. It generally takes between 5-7 days for a landed spore to become an emitter of future spores. Multiple daily applications of UVC light are recommended.

Industrial level handheld UVC light products available for cannabis or agricultural facilities vary widely. Nearly all use mercury-based fluorescent bulbs. These bulbs are usually housed inside a bulky fixture and the whole unit is connected to a fixed power source (i.e. a wall outlet via extension cord). The design origin of these products evolved from UV glue curing lamps. They are bulky, can damage plants and are difficult to maneuver in tight spaces.

Hanging UVC lights are not wholly inapplicable. But keep in mind UVC’s sanitation capabilities rely on line of sight application. Meaning any areas in shadow or blocked from direct rays will not be affected by UVC. Think of a ray of UVC light as a straight, unbendable wire. If you cannot connect the UVC light to a surface without something blocking the way (be it leaves, layers of dirt, ect.), then it will not be effective.

UVC Challenges and Solutions

Challenges existing with current agricultural UVC light products:

- Not truly portable: Most units need to be connected to a wall outlet. A long cord makes it difficult to maneuver them in rooms full of plants or other damageable products.

- Wide and bulky frames: Current designs are not plant friendly. They can cause physical damage to the plant through tearing or breaking. (i.e. Bulky designs and angular edges that grab and shred plant matter.)

- Not waterproof: When used in areas of active wetness or dampness, a higher risk of electric shock or damage to the unit exists.

- Risk of cross contamination: Fixtures are not easily to completely sanitize. Efforts to do so are tedious and time consuming. They can even void the products warranty. When placed in contact with contaminated plant matter, they become a source of contamination spread. This can jeopardize other plants or areas in the facility.

The Puren Solutions Katana was specifically designed around the needs of UVC light in the indoor growing communities. Its features are purposeful in addressing current challenges:

- Truly portable: No long cord to maneuver, no outlet required. The Katana is lightweight (21.5-ounce or 0.61 kg) and battery powered. This means powerful UVC output for all day use and long runtimes between battery charges.

- Slim, snag free design: The Katana’s long, slim design is meant to easily extend deep into plant canopies. It excels as sanitizing hard to reach places without damaging plant foliage.

- Waterproof: IP67 rated. Enjoy worry free use in damp, wet or humid environments.

- Easily and quickly sanitized: During or after each use, the main body of the Katana can be fully submerged in sanitizing solution. This eliminates the possibility of cross contamination. It also reduces the time and tedium needed to fully sanitize the unit.

A Powerful Tool for Your Arsenal

The Katana’s eight UVC LED lamps provide the most powerful light output available on the market. It provides powerful disinfection and sanitization results in less time. It was carefully crafted to enable growers to take that next step in layering their defense against powdery mildew and other contamination issues. Learn more about the Katana at www.elementgrow.com/product/katana-uvc.